We are one of the leading engineering consultants with a facility to design, manufacture and supply of Heat & Mass Transfer Equipment, Process, Chemical, Pulp and Paper and Power Plant Equipment as per ASME, ASM, API, DIN, BS, IS, HEI, IBR, TEMA, NFPA & ISO codes of practice and standards. We take pride in announcing that we have manufactured and supplied more than 1000 equipment in 4 continents and these are functioning effectively. We have a strong list of more than 300 clients and more than 50 product ranges to our credits.

We have a strong list of more than 300 clients and more than 45 product ranges to our credits. Our engineering and manufacturing organization is ably supported by our associated companies. Equipment is designed, manufactured and supplied to high quality standards and engineering practice. We have a separate Quality control manual and all our product are inspected all through the manufacturing to the completion stage by the external inspecting authorities appointed by our respective clients. We do all kind of fabrication jobs in special steels like duplex, super duplex, hasteloy, Inconel, monel, titanium like heat exhcangers, pressure vessels, dish ends, forgings, tube sheets, spools, pipe spools etc.

Manufacturing Facilities :

Profile Cutting – Pug Cutting

Welding Machines ARC, TIG, MIG – Monorail

Grinding M/c – Bending

Sandering M/c – Welding

Plate Bending / Rolling M/c – Fitment

RAW MATERIL : PLATES AND STANDARD STRUCTURAL SECTIONS AND SECTIONS FORMED FROM PLATES.

IN MATERIAL CARBON STEEL WITH GALVANISED HAND RAILINGS AND GRATINGS.

A36, A516, IS 2062, IS 1239 ETC.

WELDING PROCESS : SMAW, MIG & TIG.

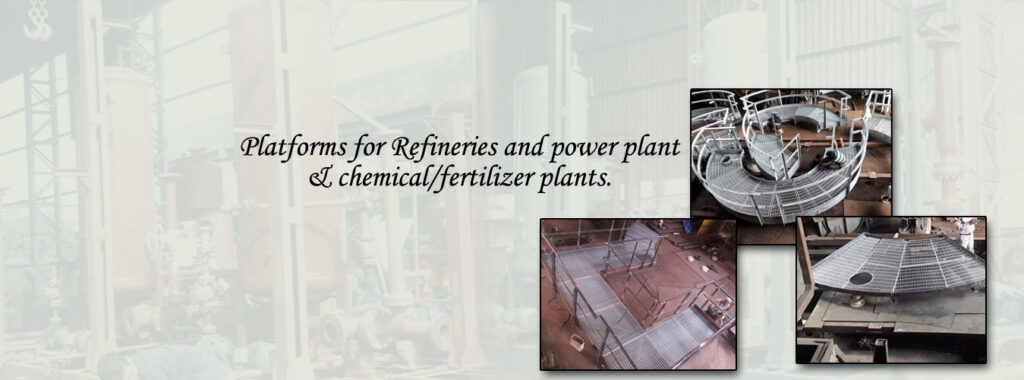

ITEMS MANUFACTURED: LADDERS AND PLATFORMS OF REFINERY EQUIPMENT.